Week 3

We finished developing a basic theoretical analysis on the shelf life of the VacuStor tube, and have started an experiment with the rise time of the tube. We first had to fabricate an experimental setup for this experiment, and now we have begun taking experimental data regarding the rise time, and we do so each day to monitor the internal pressure of the tube.

Theoretical Analysis

The shelf life of the tube is determined based on how long it can retain the vacuum. It is extremely difficult to create an impermeable tube and seal, especially one that can be mass manufactured. Hence, we want to be able to limit the permeability of gas to the best of our ability. There are two factors in determining the shelf life of the tube. One, which was already looked into, is the threshold or critical pressure. Since we know for sure the pressure in the tube will rise, it is a matter of not only what pressure that, once surpassed, makes the tube unusable, but also how quickly it reaches this pressure.

The diffusion of gas is described by Fick's First Law, and we used this equation to determine the mass transfer flux rate, which is the flux density times the surface area of the tube, or:

J is the mass transfer flux rate, which is the total rate of diffusion of gas across the entire tube. j is the flux density from Fick's First Law. A is the surface area, P is the permeability, pout and pin are the pressures outside and inside the tube respectively, A is the surface area of the tube, and δ is the thickness of the tube.This mass transfer flux rate is also the leaking rate, which we want to minimize. Hence, in order to do so, we want to have a tube with a small surface area and a large thickness with a small permeability constant, which is determined by the number of holes in the polymer structure of the tube.

The models are helpful in understanding what occurs during the experiment and what variables to focus on most when attempting to test the tube, which is what we started doing this week.

Rise Time

The rise time is the time the tube takes to equilibriate from the low pressure vacuum to standard pressure. To test this quantitatively, we created the following setup:

The vacuum gauge was sealed to the VacuStor with an epoxy, as shown:

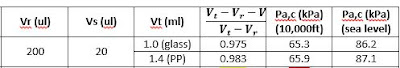

This allows the vacuum gauge to monitor the pressure inside the tube. Then, having evacuated the tube, we added a leakage port so that the surrounding pressure would be equal to atmospheric pressure. We then monitor the pressure of the inside of the tube daily so that we can determine the rise time of the tube. This will obviously take multiple weeks until results can be analyzed, but hopefully this experiment will provide useful results.

|

| Rise Time Experimental Setup |

|

| Vacuum Gauge and VacuStor Tube |